Nowadays, the use of wood veneer is still very popular, and many industries will use wood veneer. However, most customers often encounter the problem of not knowing how to choose wood veneer and slice wood veneer. Here are some methods to choose high-quality wood veneer.

Take a closer look at the veneer material: - look at the density of the material. The material of different tree species can be loose, tight, thick or thin. The veneer with tight texture is fine and smooth, with good construction strength. The finished product needs less materials for painting. On the contrary, the rough and loose wood veneer has poor texture finish, which is easy to be broken during construction, and there are many finished paint consumables after construction. Second, look at the defects of the material. If there are many knots and shadows, wormholes and wormholes, decay and discoloration, as well as resin and leather clips, it indicates that the material of the wood is poor.

The processing quality of wood veneer: the processing quality of wood veneer is one of the main criteria for splicing and non splicing. The non splicing veneer mainly depends on whether the oblique knife mark, rough burr, pollution and damage can be clearly seen on the surface of wood veneer; Whether the thickness is uniform and reaches the marked thickness; Whether the length and width conform to the marked size. In addition to checking the above conditions, special attention should be paid to whether the splicing is tight or away from the gap. If it is non-woven fabric or sticker veneer, check the bonding strength and fastness of veneer and non-woven fabric or paper. Normal gluing is not allowed to tear the veneer and non-woven fabric or paper, and the non-woven fabric or paper on the reverse side should be flat without wrinkles.

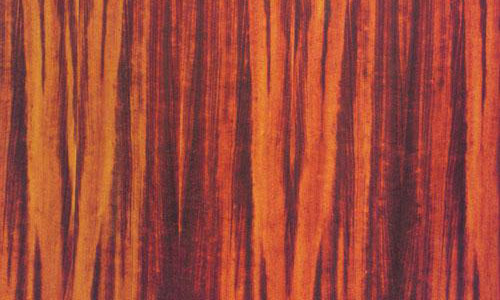

Look at the color of the veneer: the high-quality veneer and slices are fresh and tender in color, uniform everywhere, rich in the specific sub gloss of the wood, and there is no obvious natural color difference or decay discoloration. The main colors of barks of different tree species are respectively (except EP and EV barks); Red (pink, orange red, rose red, brown red, etc.), yellow (brown yellow, milk yellow, brown yellow, etc.), white (rice white), brown (black brown, brown, etc.).

Look at the wood grain: the wood grain usually has straight grain and mountain grain. A good mountain pattern should have a mountain like texture, clear veins, appropriate density, harmonious changes, and appropriate size, and should not have half mountain patterns or straight lines on both sides too wide; Good straight lines should be straight and delicate, with appropriate density, without half mountain lines or distortion.

See the actual thickness of the veneer: the thickness of the veneer is an important indicator of the texture of the veneer. The selection of thickness shall be determined by the consumer according to the actual needs of construction and consumption grade. The solid wood texture after thick skin construction is strong, while the durable strength of thin skin is weak, and its durable strength is not as good as that of thick skin.

Touch the dryness and wetness: the dryness and wetness of the veneer are professionally called moisture content. If you can feel the wetness, it means that the moisture content of the veneer is high. If it is not for panel production, it is not suitable for immediate use and needs to be dried. If it is easy to break when it is broken by hand, it indicates that the water content is low. When high-quality veneer enters the market, its moisture content must be within the range of 8~24%. In addition, corresponding measures shall be taken.

Hotline:+86-769-8378 5792

Fax:0769-85902520

Hotline:+86-769-8378 5792

Fax:0769-85902520